Applications

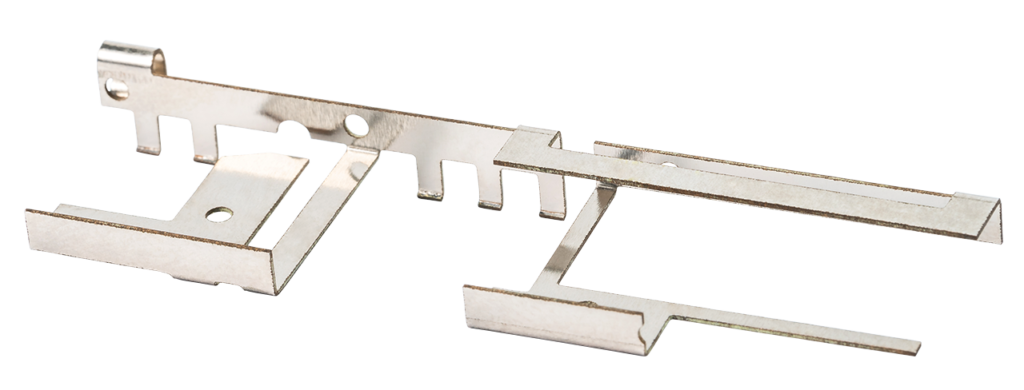

Ability to provide kinds of metal stamping parts

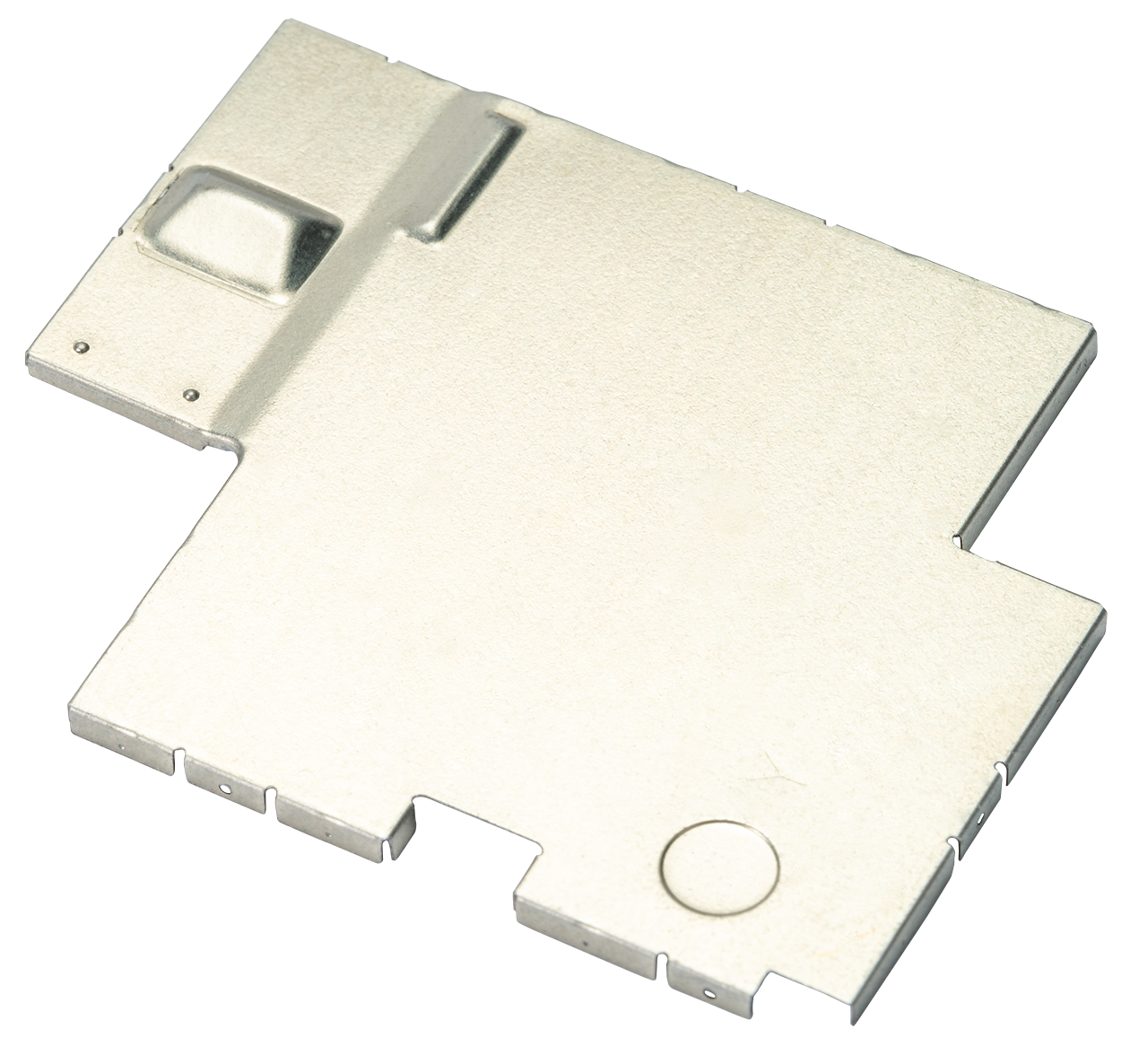

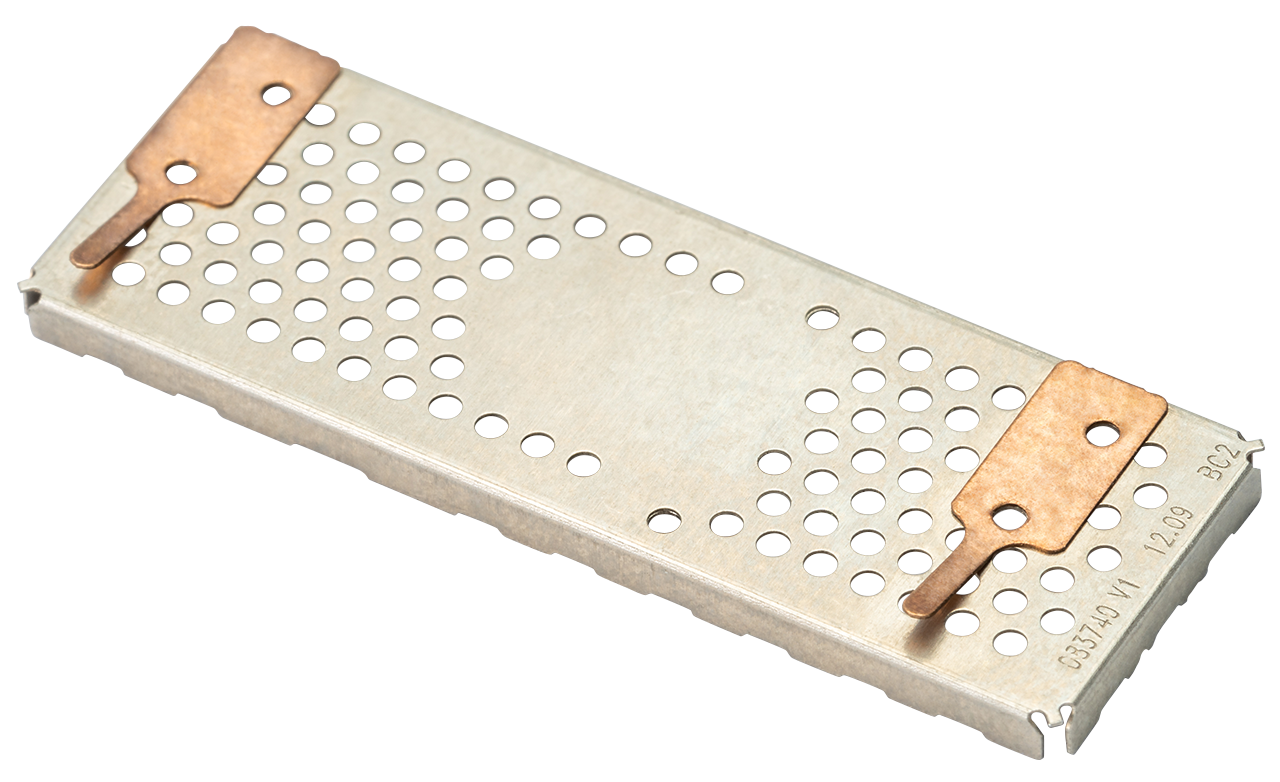

Communication Products

Consumer electrical products are trending to be thinner and lighter. Triotek can stamp for thin (<0.1mm) and uneven thickness sheet materials and provides services for material selection, product structure design, tooling development, and surface treatment to meet customer requirements.

Communication electronics are trending to be thinner and lighter, making the internals’ structure design more rigorous.

Triotek can stamp for thin and uneven thickness sheet materials and provides services for material selection, product structure design, mold development, and surface treatment to meet customer needs.

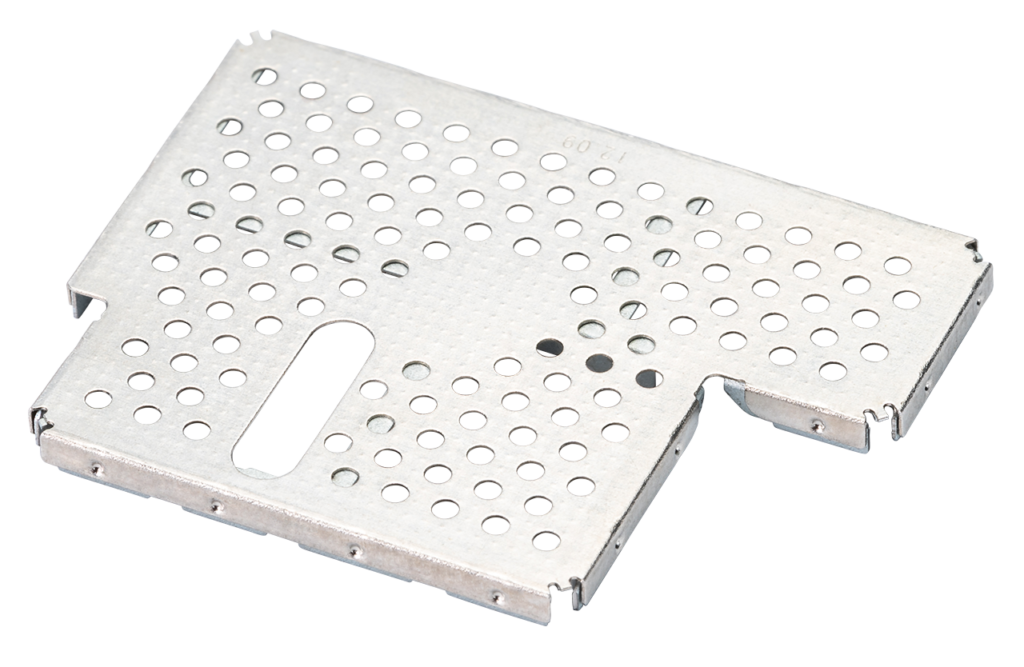

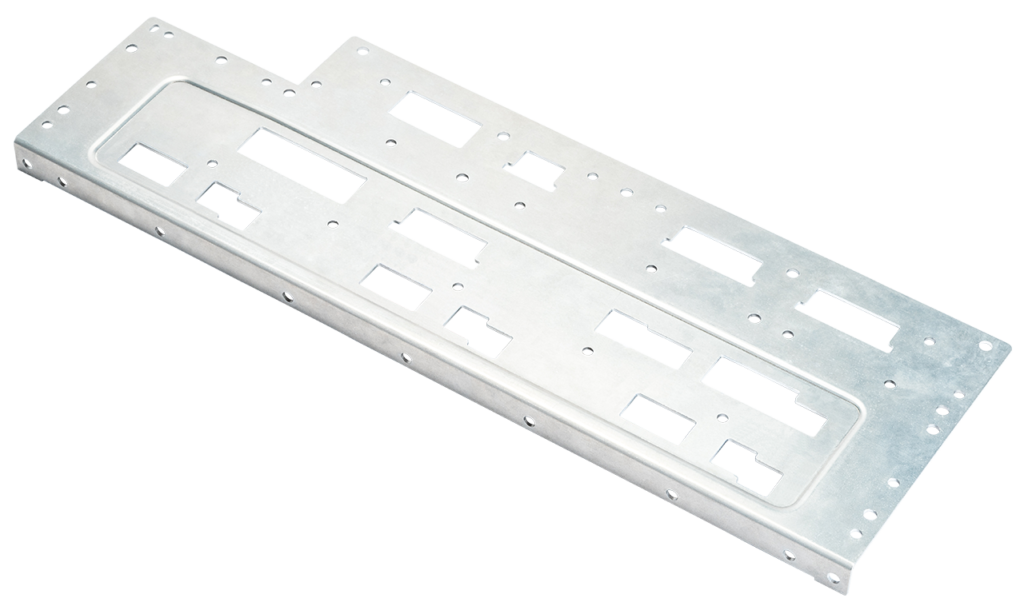

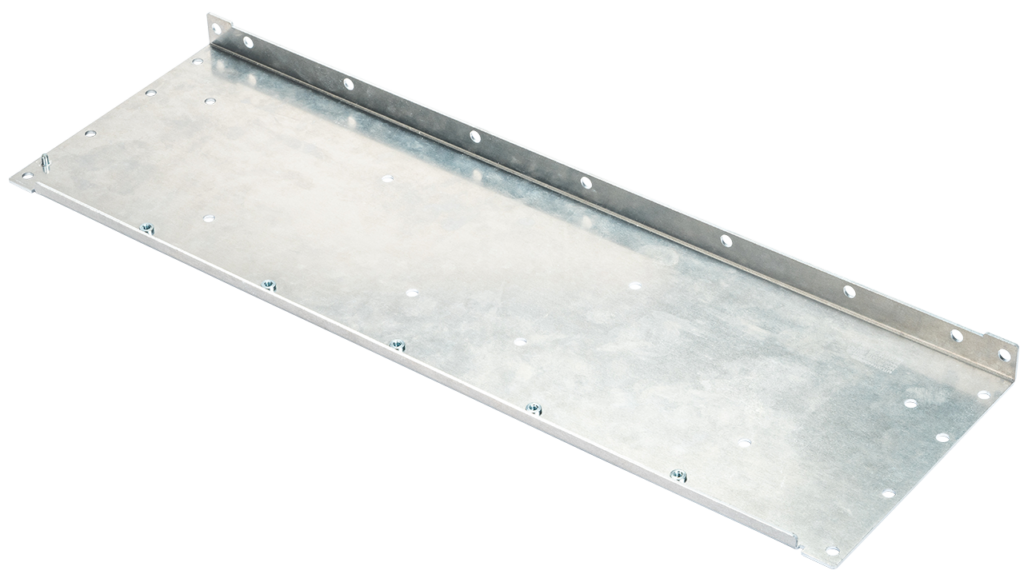

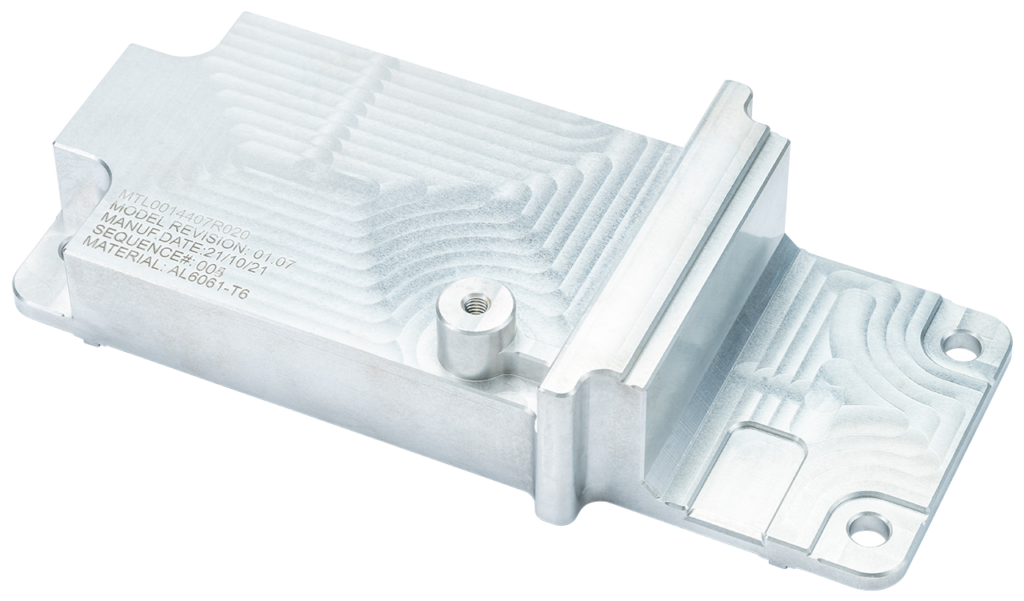

Automotive Products

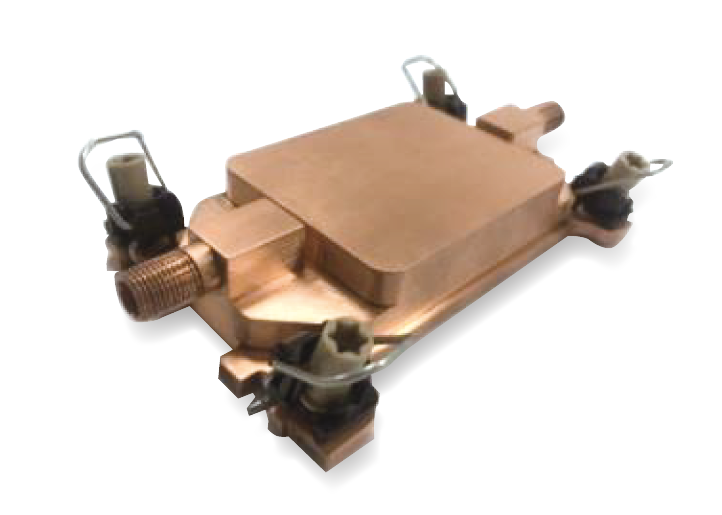

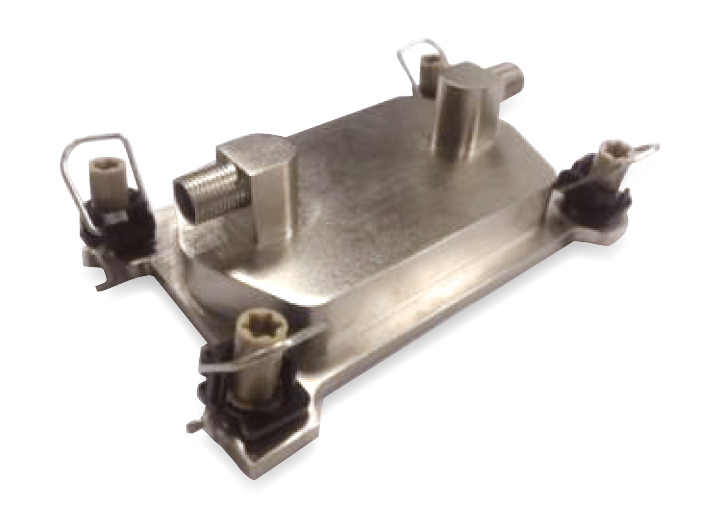

Triotek develops metal and heat dissipation parts for electric vehicles, including the EMI can, metal parts of the ECU, ADAS camera brackets and shells, cold plates, etc. Triotek provides stable fabrication quality and has acquired ROHS and IATF16949 certifications for automotive products.

Through solid supply chain integration capabilities, Triotek can meet customers’ needs in different processes such as stamping, CNC, die-casting, and secondary processing.

Through strong supply chain integration capabilities, Triotek can meet customers’ needs in different processes such as stamping, CNC, die-casting, and kinds of secondary processing.

Triotek develops metal and heat dissipation parts for electric vehicles, including the EMI can, metal parts of the ECU, ADAS camera brackets and shells, cold plates, etc. Triotek has the ability to stabilize delivery quality and has acquired ROHS and IATF16949 certification for automotive products.

Through strong supply chain integration capabilities, Triotek can meet the needs of customers in different processes such as stamping, CNC, die-casting, and kinds of secondary processing.

Triotek develops metal and heat dissipation parts for electric vehicles, including the EMI can, metal parts of the ECU, ADAS camera brackets and shells, cold plates, etc. Triotek has the ability to stabilize delivery quality and has acquired ROHS and IATF16949 certification for automotive products.

Triotek develops metal and heat dissipation parts for electric vehicles, including the EMI can, metal parts of the ECU, ADAS camera brackets and shells, cold plates, etc. Triotek has the ability to stabilize delivery quality and has acquired ROHS and IATF16949 certification for automotive products.

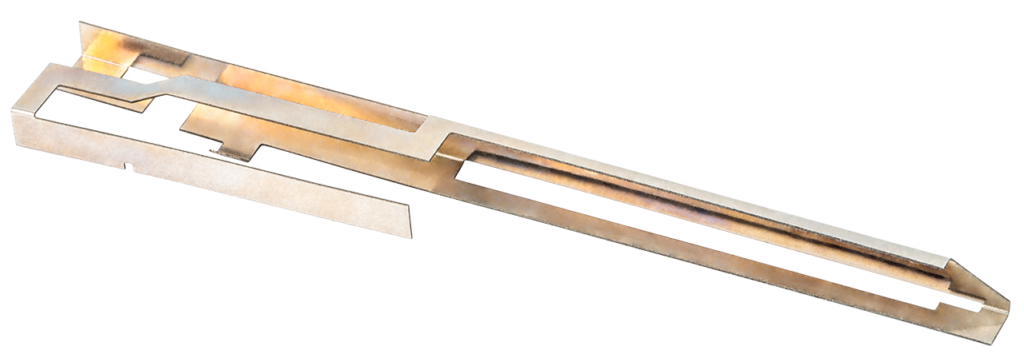

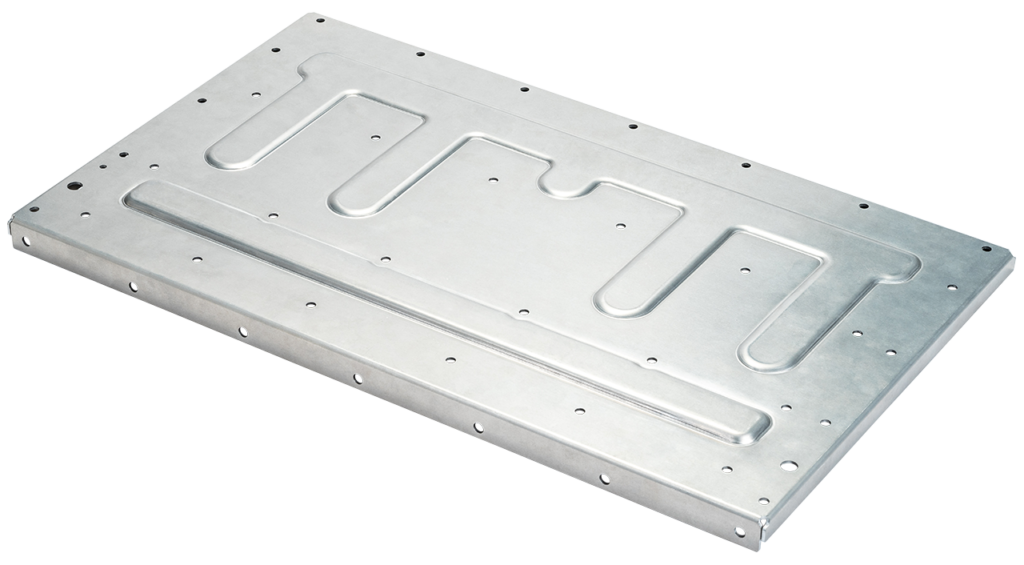

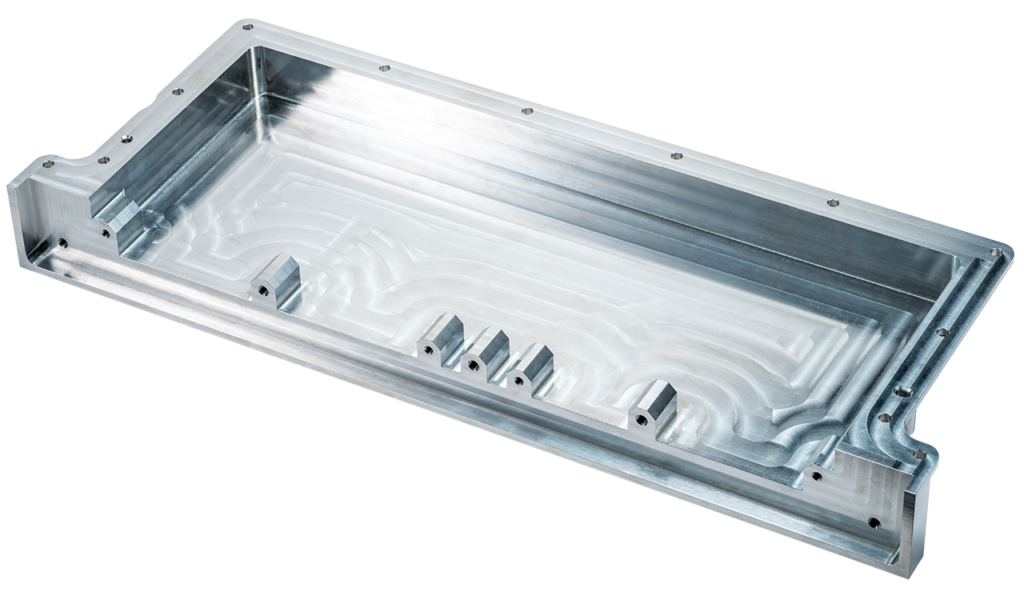

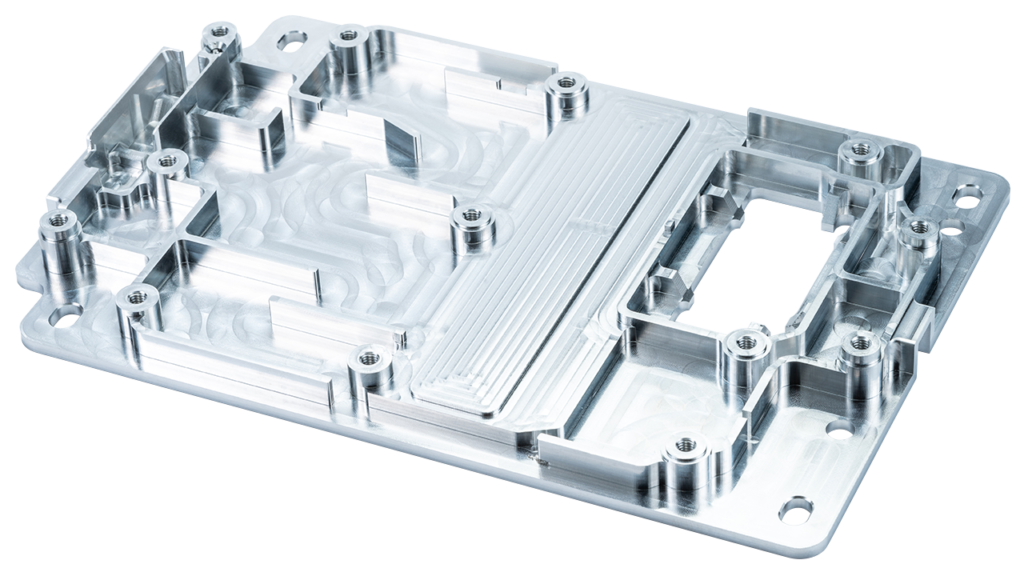

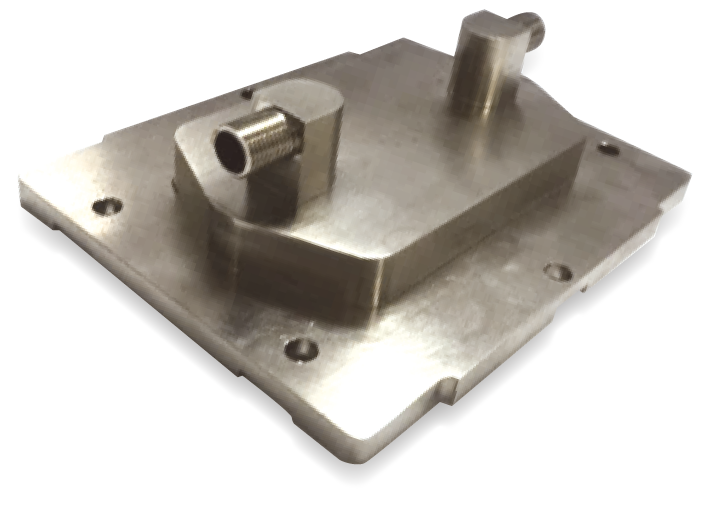

Liquid Cooling Products

Design and provide heat dissipation simulation analysis according to customer needs to provide optimal solutions, and provide lightweight water-cooled plate products through friction stir welding technology.

依據客戶需求設計及提供散熱模擬分析以提供最佳化解決方案,透過攪拌磨擦焊接技術,提供輕量化之水冷板產品。