Core Competencies and Services

Provide customers with accurate and efficient solutions

Core Competitiveness

Tooling Design Capability

Professional tooling design center can provide customers with professional advice

based on simulation resource in early stage of development and optimize overall project efficiency.

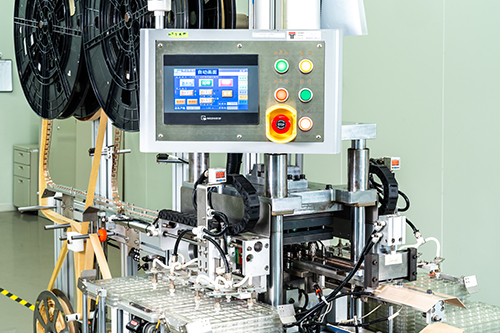

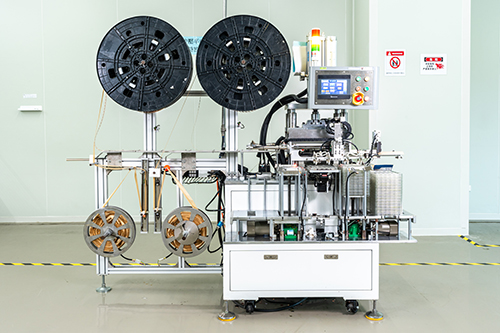

Automation Capability

Automation equipment for products and development of specialized intelligent equipment. Ability to suggest different schemes to meet product requirements through customer discussion.

Research and Development Capability

Provide customized services and continually innovative designs and technologies, from simulation analysis, design, verification and optimization, process advice, proofing, and mass production, to meet customers’ various needs and provide optimized production solutions.

Value Chain Integration Capability

In response to market and customer needs, we integrate third-party resources and become a one-stop solution provider.

Core Team

- Manufacture

- Research and Design

- Quality Assurance

- Management

Our professional tooling design center can provide solutions for product design based on program simulation to optimize the development schedule. Moreover, to provide services including proto/prograssive tooling design, assembly, and verification with thin (<0.1mm) or uneven thickness materials.

Core Team

- Manufacture

- Research and Design

- Quality Assurance

- Management

Capability to integrated different kinds of process; professional support for material selection, product structure design, tooling development, surface treatment, and other technical evaluations to meet our client’s requirements and create the core values of professional manufacturing.

Core Team

- Manufacture

- Research and Design

- Quality Assurance

- Management

Triotek maintains high-quality products and headways for better improvement.

Triotek has acquire ISO14001, ISO9001, and multiple certification and earns the recongition from our worldwide customers.

In the mean time, Triotek continuously particiated for environment sustainability

Core Team

- Manufacture

- Research and Design

- Quality Assurance

- Management

Triotek settle on a mission of “being a company to earn stable profits and maintain a good reputation to reward investors and employees.” We would cooperate with our customers to build a high-quality team, the AI automotive manufacturer, and facilitate ESG to reach Sustainable development between 2022 and 2025.

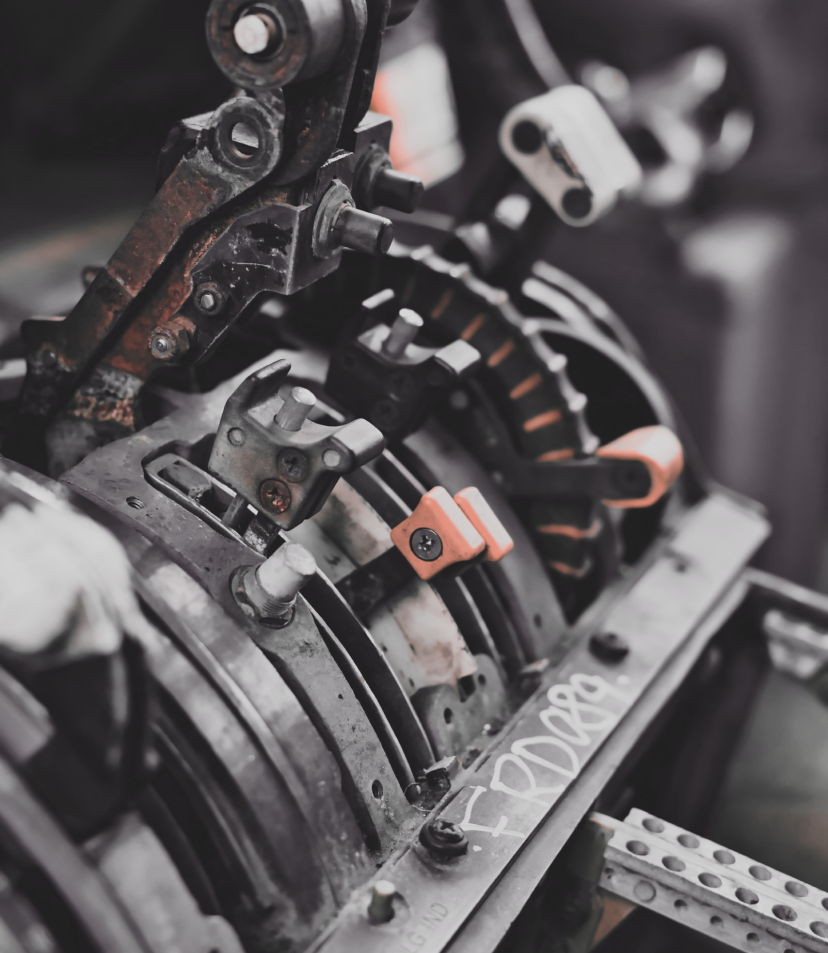

Productive Capabilities

Stamping

- Tooling design – Triotek has the capability of progressive/engineer tooling design, assembly, verify for the precision parts

- Simulation and analysis- Find and solve potential issues to prevent unnecessary lost with cost savings.

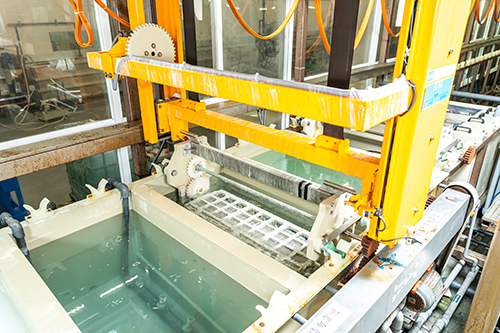

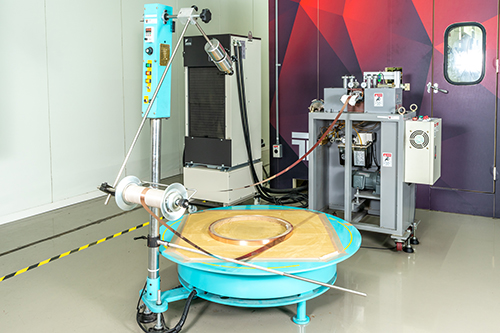

Welding

- Laser welding- Bonding the thin materials (0.065mm) by high density welding points

- Friction welding- apply at the part with hollow structure and avoid from uneven welding.

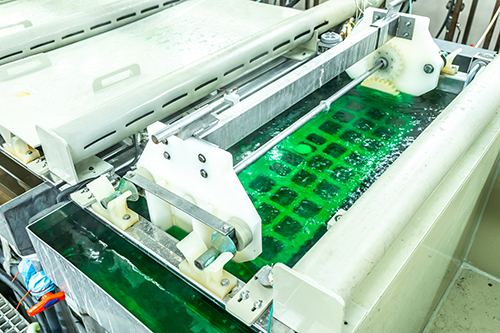

Surface treatment

- Electroless Ni plating- Immersed in the plating reagent and formed an anti-oxidation Ni layer on the metal surface, it can be applied for the complex structure parts.

- Insulation paint coating- Coating an ultra-thin insulation layer on the surface through a unique technique.

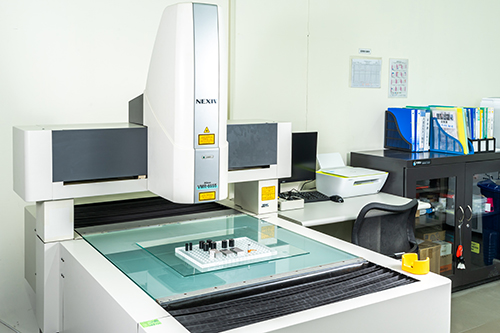

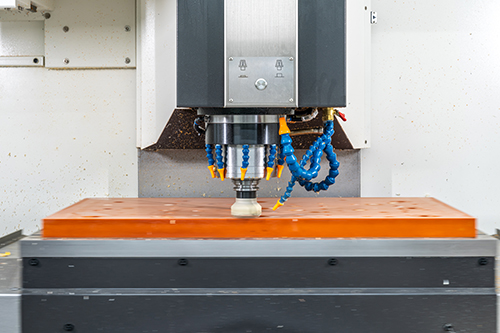

CNC

- Provide excellent precision and complex products with high rotational speed CNC and CCD inspection systems.

Thermal system design service

Equipment Pictures